In the intricate realm of construction engineering, the engine shutoff solenoid valve stands as a crucial component, vital for the safe and efficient operation of various vehicles. This article aims to elucidate the internal workings of this key device, providing insights into its functionality and significance.

Introduction to Engine Shutoff Solenoid

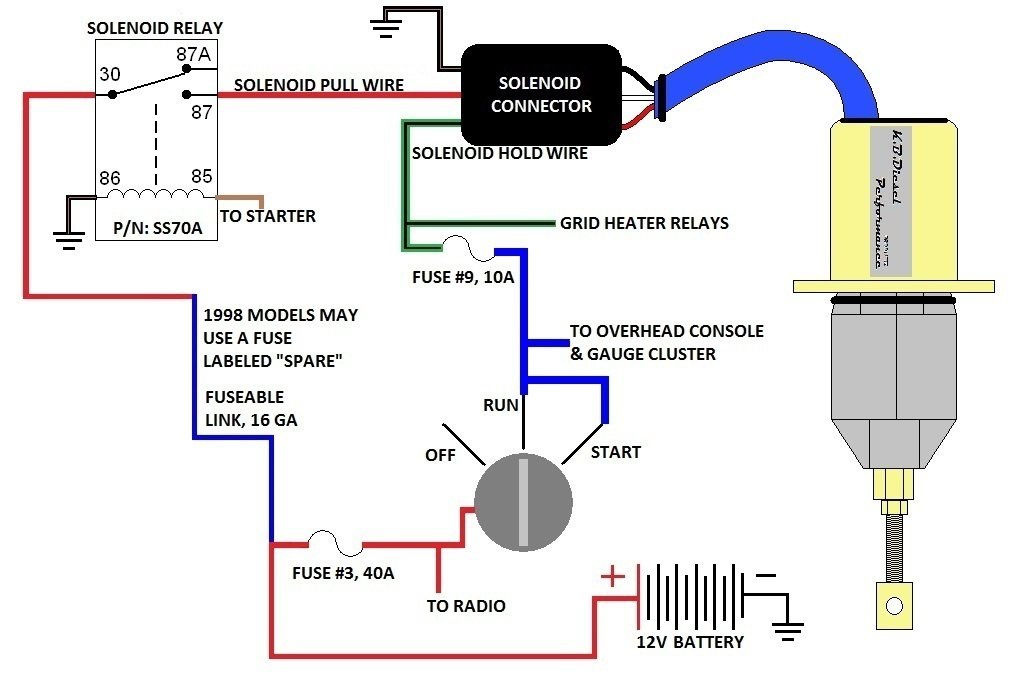

Engine shutoff solenoid valves, also referred to as fuel shutoff solenoid valves or stop solenoids, are electromechanical devices tasked with regulating the flow of fuel to the engine. Typically found in diesel engines, these valves serve the crucial function of halting the fuel supply to the engine in emergency situations or when the ignition is deactivated.

How an Engine Shutoff Solenoid Valve Operates

1.Fundamental Principle: At the core of the engine shutoff solenoid valve lies the principle of electromagnetism. It comprises a coil of wire wound around a movable plunger linked to a valve mechanism.

2.Normal Functionality: During regular engine operation, the solenoid valve remains energized, ensuring an open flow of fuel to sustain the engine's smooth performance.

3.Shutoff Sequence: Upon the deactivation of the ignition or in case of an emergency, power to the solenoid coil is interrupted. This action causes the magnetic field to collapse, prompting the plunger to retract or shift, consequently closing the valve and ceasing the fuel supply to the engine.

4.Enhanced Safety and Efficiency: The rapid response time of the solenoid valve guarantees a prompt engine shutoff during critical scenarios, bolstering safety measures and averting potential engine damage.

Applications of Engine Shutoff Solenoid Valves

Engine shutoff solenoid valves find widespread utility across diverse vehicles and equipment, including diesel generators, agricultural machinery, construction equipment, and marine engines. Their dependable and effective operation renders them indispensable for ensuring the secure and controlled shutoff of engines in varied applications.

:max_bytes(150000):strip_icc()/solenold20valve20on20tractor20transmission20control5B15D-2000-63d6a4ba913f4b63acb140140aa9da91.jpg)

Conclusion

In summary, the engine shutoff solenoid valve emerges as a critical component pivotal to the safe and efficient functioning of diesel engines. A comprehensive grasp of the operational intricacies of this electromechanical device is imperative for upholding the performance and reliability of vehicles and equipment reliant on this technology. Through diligent maintenance practices and timely valve replacements, vehicle owners and operators can elevate the safety standards and longevity of their engines.