In the realm of electrical engineering and industrial automation, contactors play a pivotal role in controlling electrical circuits. Whether you're working on a small-scale project or managing a large industrial system, understanding the functionality and importance of contactors is essential. This blog will delve into the world of contactors, exploring their types, applications, and significance in modern electrical systems.

What Are Contactors?

A contactor is an electromagnetic switch used to connect or disconnect electrical circuits. Unlike manual switches, contactors are designed to handle high current loads and are typically controlled by an external signal, such as a voltage or current applied to a coil. They are widely used in industrial and commercial settings where frequent switching of large electrical loads is required.

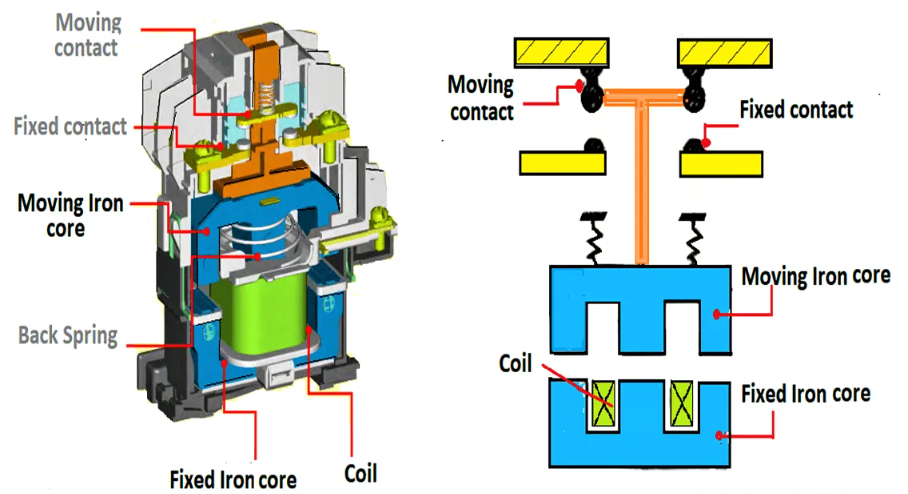

How Do Contactors Work?

The working principle of the contactor is: when the contactor coil is energized, the coil current will produce a magnetic field, the generated magnetic field will make the static iron core produce electromagnetic suction to attract the iron core, and drive the AC contactor point action, normally closed contact is disconnected, normally open contact is closed, the two are linked. When the coil is powered off, the electromagnetic suction disappears, the armature is released under the action of the release spring, so that the contact is restored, the normally open contact is disconnected, and the normally closed contact is closed.

The key components of a contactor include:

- Coil: The coil generates the magnetic field when energized.

- Contacts: These are the points where the electrical connection is made or broken.

- Arc Suppression System: This system helps to extinguish arcs that are created when contacts open or close.

- Mechanical Structure: This includes the frame, spring, and other mechanical parts that hold the contacts in place.

Types of Contactors

Contactors can be classified based on the type of current they handle:

- AC Contactors: Designed for alternating current (AC) circuits, these contactors are commonly used in industrial machinery, lighting systems, and motor controls.

- DC Contactors: Used for direct current (DC) circuits, DC contactors are often found in applications like electric vehicles, renewable energy systems, and battery management.

Other classifications include:

- Rated Voltage and Current: Contactors are available in various voltage and current ratings to suit different applications.

-

Pole Configuration: They can be single-pole, double-pole, or multi-pole, depending on the number of circuits they control.

Applications of Contactors

Contactors are indispensable in numerous electrical systems. Some of their primary applications include:

- Motor Control: They are used to start, stop, and control the speed of motors.

- Power Distribution: Contactors help in distributing power to different parts of a system.

- Automation Systems: In industrial automation, contactors are used to control the operation of machinery and equipment.

- Lighting and HVAC Systems: They are used to control large lighting loads and HVAC (Heating, Ventilation, and Air Conditioning) systems.

Advantages of Using Contactors

- High Current Capacity: Contactors can handle high current loads, making them suitable for industrial applications.

- Remote Control: They can be controlled from a distance, which is crucial in hazardous environments or for large-scale systems.

- Durability: Designed to withstand frequent switching operations, contactors are built to last.

- Safety: Contactors are equipped with arc suppression systems, which reduce the risk of electrical arcs causing damage or injury.

Choosing the Right Contactor

Selecting the appropriate contactor for your application is critical to ensure optimal performance and safety. Key factors to consider include:

- Rated Current and Voltage: Ensure the contactor can handle the maximum current and voltage of your system.

- Pole Configuration: Choose the right pole configuration based on the number of circuits you need to control.

- Duty Cycle: Consider how frequently the contactor will be used and select one that can handle the required duty cycle.

- Environmental Conditions: Factors like temperature, humidity, and exposure to dust or moisture can affect the performance of a contactor.

Maintenance and Safety

Like any electrical component, contactors require regular maintenance to ensure they function correctly. This includes:

- Cleaning: Removing dust and dirt from the contacts to prevent corrosion.

- Inspecting the Arc Suppression System: Ensuring that the arc suppression system is functioning properly to prevent damage from electrical arcs.

- Testing: Regularly testing the contactor to ensure it is operating within its specifications.

Safety should always be a top priority when working with contactors. Always follow proper safety protocols and consult the manufacturer's guidelines when installing, maintaining, or repairing contactors.

The Future of Contactors

As technology continues to evolve, so do contactors. Modern advancements include:

- Smart Contactors: These contactors are equipped with sensors and can communicate with other devices, enabling advanced monitoring and control.

- Energy Efficiency: New designs focus on reducing energy consumption and improving efficiency.

- Improved Reliability: Enhanced materials and manufacturing techniques are leading to more durable and reliable contactors.

Conclusion

Contactors are fundamental components in electrical systems, providing the means to control high current loads efficiently and safely. Whether you're working on a small project or managing a large industrial system, understanding the types, applications, and maintenance of contactors is crucial. As technology advances, contactors will continue to play a vital role in the future of electrical engineering and automation.

If you have any questions or need further clarification on contactors, feel free to reach out!