Hydraulic systems are the backbone of modern machinery, enabling precise control of fluid flow to perform heavy-duty tasks. At the heart of these systems lies the hydraulic valve, and within the valve, the coil plays a crucial role in controlling its operation. In this blog, we’ll delve into the world of hydraulic valve coils, exploring their function, types, and applications.

What is a Hydraulic Valve Coil?

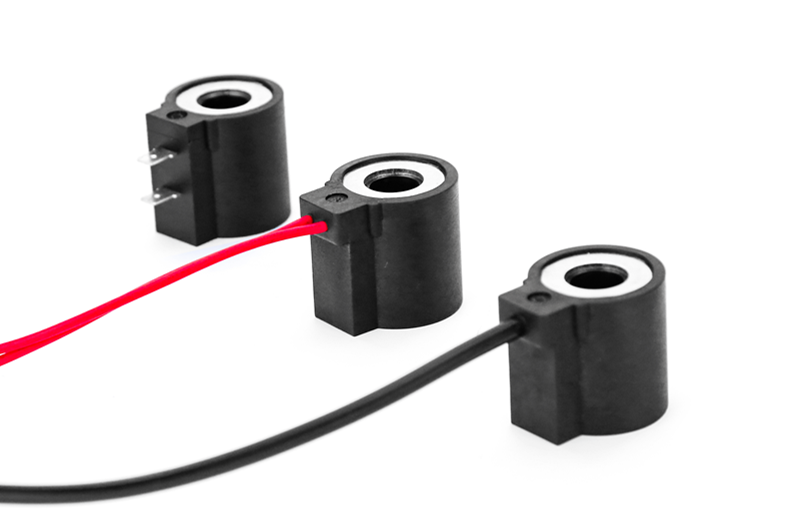

A hydraulic valve coil, also known as a solenoid coil, is an electromagnetic component used to control the operation of a hydraulic valve. It generates a magnetic field when an electric current flows through it, which in turn activates or deactivates the valve. The coil is typically wound around a ferromagnetic core, and its primary function is to convert electrical energy into mechanical motion to regulate the flow of hydraulic fluid.

How Does a Hydraulic Valve Coil Work?

1.Electromagnetic Induction: When an electrical current passes through the coil, it creates a magnetic field.

2.Activation of the Valve: The magnetic field attracts a ferromagnetic plunger or armature, causing it to move and open or close the valve.

3.Fluid Flow Control: The movement of the plunger regulates the flow of hydraulic fluid through the valve, enabling precise control of pressure, direction, or volume.

Hydraulic valve coils are designed to operate in conjunction with different types of valves, including directional control valves, pressure relief valves, and flow control valves.

Types of Hydraulic Valve Coils

1.Normally Open (N.O.) Coils

These coils remain open when no power is applied. They close when an electrical current flows through the coil.

2.Normally Closed (N.C.) Coils

These coils remain closed when no power is applied. They open when an electrical current flows through the coil.

3.Pilot Operated Coils

These coils are used in pilot-operated valves, where a small amount of fluid is used to control the flow of a larger volume of fluid.

4.High-Frequency Coils

Designed for high-speed applications, these coils are optimized for rapid switching and precise control.

Key Features and Performance Parameters

Rated Voltage: The voltage required to activate the coil, typically ranging from 12V to 24V DC or higher for industrial applications.

Power Rating: The electrical power consumption of the coil, measured in watts (W).

Resistance: The resistance of the coil, measured in ohms (Ω), which determines the current draw.

Life Expectancy: The expected lifespan of the coil, which depends on factors like operating conditions, duty cycle, and quality of materials.

Applications of Hydraulic Valve Coils

Hydraulic valve coils are widely used across various industries due to their versatility and reliability. Some common applications include:

1.Construction Machinery

Hydraulic coils are used in excavators, bulldozers, and cranes to control the movement of hydraulic cylinders and actuators.

2.Automotive Industry

In vehicles, coils are used in automatic transmissions, power steering systems, and braking systems.

3.Aerospace and Defense

Hydraulic coils are critical in aircraft landing gear, flight control systems, and military equipment.

4.Manufacturing and Automation

Coils are used in hydraulic presses, robotic systems, and industrial machinery to control fluid flow and pressure.

5.Marine and Offshore

Hydraulic coils are used in shipboard systems, oil rigs, and underwater equipment for precise fluid control.

Advantages of Hydraulic Valve Coils

Precision Control: Hydraulic coils provide accurate and repeatable control of fluid flow.

Durability: Designed to withstand harsh operating conditions, including high temperatures, vibrations, and moisture.

Compact Design: Coils are lightweight and compact, making them ideal for space-constrained applications.

Low Maintenance: With proper installation and usage, hydraulic coils require minimal maintenance.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of hydraulic valve coils, regular maintenance is essential:

1.Inspect for Damage: Check for signs of wear, corrosion, or physical damage to the coil or wiring.

2.Clean the Contacts: Dirt or debris on the contacts can cause poor electrical connections.

3.Test Electrical Connections: Use a multimeter to check for continuity and resistance in the coil.

4.Replace Faulty Coils: If a coil is damaged or malfunctioning, replace it promptly to avoid system failure.

The Future of Hydraulic Valve Coils

As technology advances, hydraulic valve coils are becoming more efficient and intelligent. Innovations such as energy-efficient designs, smart sensors, and integrated control systems are making hydraulic systems more precise and sustainable. Additionally, the trend toward miniaturization is enabling coils to be used in compact and portable hydraulic applications.

Conclusion

Hydraulic valve coils are indispensable components in modern hydraulic systems, enabling precise control of fluid flow and pressure. Understanding their function, types, and applications is essential for anyone working with hydraulic machinery. By prioritizing proper maintenance and staying updated with technological advancements, you can ensure reliable performance and extend the lifespan of your hydraulic systems.

Our shop recently launched a lot of new products of solenoid coil, click the picture below to explore.